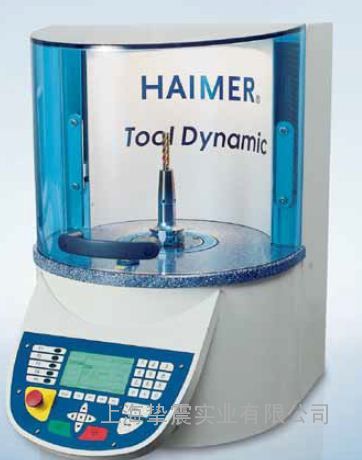

HAIMER 动平衡机

动平衡技术/Balancing Technology

模块化动平衡系统/Modular Balancing System

台式/TD 1002 4

经济型/TD 2009 Economic 6

经济增强型/TD 2009 Economic Plus 8

舒适型/TD 2009 Comfort 10

舒适增强型/TD 2009 Comfort Plus

刀具动平衡控制终端/Tool Dynamic Control Terminal

刀具动平衡机TD4.0软件/Tool Dynamic TD Software 4.0

12

19

18

可选配置/Optional Configurations 14

动平衡机软件TD4.0/Tool Dynamic TD Software 4.0

刀具平衡与测量/Tool Balancing and Presetting

TD Preset 20

特殊的动平衡机/Special Balancing Machines

TD 800 22

全自动刀具动平衡机/Automatic Balancing Technology

TD 2010 Automatic 24

模块化动平衡系统

Tool Dynamic 刀具动平衡机

Modular balancing system

目录

CONTENT

HAIMER 动平衡机 页数/Page

动平衡技术/Balancing Technology

模块化动平衡系统/Modular Balancing System

台式/TD 1002 4

经济型/TD 2009 Economic 6

经济增强型/TD 2009 Economic Plus 8

舒适型/TD 2009 Comfort 10

舒适增强型/TD 2009 Comfort Plus

刀具动平衡控制终端/Tool Dynamic Control Terminal

刀具动平衡机TD4.0软件/Tool Dynamic TD Software 4.0

12

19

18

可选配置/Optional Configurations 14

动平衡机软件TD4.0/Tool Dynamic TD Software 4.0

刀具平衡与测量/Tool Balancing and Presetting

TD Preset 20

特殊的动平衡机/Special Balancing Machines

TD 800 22

全自动刀具动平衡机/Automatic Balancing Technology

TD 2010 Automatic 24

应用案例/Application Examples 28

附件/Accessories 31

2 技术数据变更恕不通知

Technical data subject to change without prior notice

5.

!

–Preservation of warranty in case of

machine tool spindle damages

刀具动平衡优势

THE TOOL DYNAMIC ADVANTAGES

1. Enable the full potential of your

machine tool

–Higher RPMs

–Higher cutting capacity

–Better surface finish

能使你的机床发挥*大潜能

- 更高的转速

- 更高的切削能力

- 更好的表面光洁度

保护你的机床

- 更少的震动

- 降低轴承磨损

- 延长主轴寿命

- 生产质量控制 预平衡刀柄

- 保护机床主轴不受损坏

减少你的加工成本

- 更少的停机时间

- 更高的工艺可靠性

准确而便捷的动平衡操作

- 人性化的操作软件

- 不需要平衡方面的专家来操作

HAIMER是你机床系统方案的提供者

- 完美的平衡源于简单的方案

- 平衡——夹持——自动化

使用平衡刀具 ,你可以在四个方面

节省成本

- 更高的切削量

- 延长主轴寿命

- 更长的刀具寿命

- 得到更好的表面加工质量

3 技术数据变更恕不通知

Technical data subject to change without prior notice

Tool Dynamic TD 1002:

台式刀具动平衡机

用于基础动平衡/For minimalists

4 技术数据变更恕不通知

Technical data subject to change without prior notice

动平衡机在单或双平面调节平衡

- 台式动平衡机

- 模具制造商的理想选择

- 针对小批量生产, 简单应用和标准刀柄

- 自动夹持的转换套

- 合理价格(不含电脑)

特点

- 基础操作界面—集成用户界面和显示界面

- 自动锁紧的安全罩

特点/Characteristics

Adapted table for optimized base

技术参数/Technical details

Tool Dynamic TD 1002

尺寸/Dimensions [mm]

重量/Weight [kg]

主轴转速/Spindle speed [rpm]

测量精度/Measuring accuracy [gmm]

电源需求/Power requirements [V/Hz]

500×680×820

200kg

300-1100

<1

230/50-60

功率/Power usage [kW]

气源/Compressed air [bar]

*大刀柄长度/max. tool length [mm]

*大刀柄直径/max. tool diameter [mm]

*大刀柄重量/max. tool weight [kg]

低震动底座

Vibration optimised base

德语/英语/法语/西班牙语/意大利语

单平面动平衡测量功能

Balancing in 1 plane

用户界面

User interface

光学指引帮助

Optical indexing help

激光标记

Laser marking

标签打印接口

Print label

径向钻孔去重标示软件

Drilling radial

精确测量

Index balancing

主轴补偿平衡测量功能

Balancing with spindle compensation

动平衡环配重标示软件

Software for compensation with

balancing rings

附件和特殊装置

Accessories and special equipment

可调底座来减缓震动

操作界面的语言

在单平面测量和补偿不平衡量

(静态)

集成操作界面便于操作

显示精确的主轴角度位置

标记不平衡位置和改进位置

可与打印机连接,在标签上

打印结果

径向钻孔调整平衡

测试过程中的误差补偿(2次

测量,旋转180°精确测量)

快速精确地测量重复部分(简

单测量运行时)

用平衡环或者其它移动方式

调平衡

从14页开始介绍Please check the table from page 14

技术数据变更恕不通知/Technical data subject to change without prior notice

5 技术数据变更恕不通知

Technical data subject to change without prior notice

Tool Dynamic TD 2009 Economic:

经济型刀具动平衡机TD 2009

用于初始动平衡/For beginners

6 技术数据变更恕不通知

Technical data subject to change without prior notice

你将从Tool Dynamic TD2009 型动平衡机进入模块化系统。

Tool Dynamic TD2009经济型动平衡机能单平面测量和补偿

(静止)。因此非常适用于短刀柄和双面不平衡量较低的刀

具。集成的键盘和显示屏幕使操作十分简单。

技术数据变更恕不通知/Technical data subject to change without prior notice

TOOL DYNAMIC TD 2009 ECONOMIC

模块化动平衡系统/MODULAR BALANCING SYSTEM

特点/Characteristics

单平面动平衡测量功能

Balancing in 1 plane

用户界面

User interface

附件和特殊装置

Accessories and special equipment

底座由特殊材料制成

Base made of polymer concrete

Integrated user interface for easy handling of

the machine

Tool Dynamic TD 2009 Economic

气源/Compressed air [bar]

*大刀柄长度/max. tool length [mm]

选项/optional [mm]

*大刀柄直径/max. tool diameter [mm]

选项/optional [mm]

*大刀柄重量/max. tool weight [kg]

6

400

700

380

425

30

订货号/Order No. 80.220.00.09

Measuring and compensation of unbalance

in 1 plane (static)

Please check the table from page 14

Highest measuring accuracy due to

heavy base

光学指引帮助

Optical indexing help

Indication of the exact spindle angle position

on display

激光标记

Laser marking

Indicates the position of unbalance and

correction with a laser

标签打印接口

Print label

Print balancing result on label

径向钻孔去重标示软件

Drilling radial

精确测量

Index balancing

主轴补偿平衡测量功能

Balancing with spindle compensation

Balancing by drilling radially

Compensation of measuring errors by index

balancing (2 measuring runs, indexing angle

180°)

Quick and precise measurement of repetition

parts (single measuring run)

动平衡环配重标示软件

Software for compensation with

balancing rings

Balancing by rings or other movable weights

德语/英语/法语/西班牙语/意大利语

在单平面测量和补偿不平衡量

(静态)

集成操作界面便于操作

从14页开始介绍

高精度的测量必须建立在稳重的

底座基础上

显示精确的主轴角度位置

用激光标示不平衡位置和改进

位置

可与打印机连接,在标签上

打印结果

通过径向钻孔达到平衡

测试过程中的误差补偿(2次测

量,旋转180°精确测量)

快速精确地测量重复部分(简单

测量运行时)

用平衡环或者其它移动方式调平

衡

操作界面的语言 Languages for user interface

技术参数/Technical details

尺寸/Dimensions [mm]

重量/Weight [kg]

主轴转速/Spindle speed [rpm]

测量精度/Measuring accuracy [gmm]

电源需求/Power requirements [V/Hz]

功率/Power usage [kW]

500×1500×820

450

300-1100

<0.5

230/50-60

0.4

7 技术数据变更恕不通知

Technical data subject to change without prior notice

Tool Dynamic TD 2009 Economic Plus:

TD 2009 经济增强型刀具动平衡机

针对高级用户/For the advanced

8 技术数据变更恕不通知

Technical data subject to change without prior notice

9

新款 TD 2009 经济增强型对于双平面测量来说是十分完美的

(动态)。 长的刀柄需要双平面动平衡来校正不平衡量。

机器附件可以整齐的排列在内置的抽屉里面,通过激光标示,

工作快速并准确,光学指引帮助并自动找寻主轴角度。

可以使用平衡螺钉来调整刀柄的动平衡。

技术数据变更恕不通知/Technical data subject to change without prior notice

TOOL DYNAMIC TD 2009 ECONOMIC PLUS

模块化动平衡系统/MODULAR BALANCING SYSTEM

如下的功能和 Tool Dynamic TD 2009 经济型一样

The following characteristics are identical to Tool Dynamic TD 2009 Economic:

下面的功能是Tool Dynamic TD 2009 经济增强型标准配置的

The following characteristics are standard inclusive for Tool Dynamic TD 2009 Economic Plus:

The new TD 2009 Economic Plus is perfect to measure unbalance in two

planes (dynamic). Long tools have to be balanced in two planes to correct

also the couple or dynamic unbalance.

Accessories can be clearly arranged in the built in drawers. Work quickly

and error free with laser marking, optical indexing help and automatic

indexing of the spindle.

The “fixed components” allow to balance with screws at rotors with

threaded bores.

特点/Characteristics

特点/Characteristics

单平面动平衡测量功能

balancing in 1 plane

光学指引帮助

Optical indexing help

用户界面

User interface

激光标记

Laser marking

附件和特殊装置

Accessories and special equipment

技术参数/Technical details

Tool Dynamic TD 2009 Economic Plus

尺寸/Dimensions [mm]

重量/Weight [kg]

主轴转速/Spindle speed [rpm]

测量精度/Measuring accuracy [gmm]

电源需求/Power requirements [V/Hz]

功率/Power usage [KW]

气源/Compressed air [bar]

*大刀柄长度/max. tool length [mm]

选项/optional

*大刀柄直径/max. tool diameter [mm]

选项/optional

*大刀柄重量/max. tool weight [kg]

订货号/Order No. 80.222.00.09

双平面动平衡测量功能

Balancing in 2 planes

Measuring and compensation of unbalance

in 2 planes (dynamic unbalance)

固定位置调平衡

Fixed components

Enables balancing at predefi ned positions,

e. g. with balancing screws

自动定位

Automatic indexing

Turns the spindle on the selected angle position

and simplifi es exact positioning of spindle

附件架

Rack for accessories

从14页开始介绍

在双平面测量和补偿动平衡

(动态)

在预定位置平衡调节 比如:

使用动平衡螺钉

主轴能自动旋转到选定角度

位置

储存架带两个集成的抽屉可

以储存转换套或者其它附件

Storage rack with two integrated drawers for

balancing adapters and further accessories

Please check the table from page 14

特殊材料的底座

Base made of polymer concrete

标签打印接口

Print label

径向钻孔去重标示软件

Drilling radial

精确测量

Index balancing

主轴补偿测量功能

Balancing with spindle compensation

动平衡环配重标示软件

Software for compensation with

balancing rings

德语/英语/法语/西班牙语/

意大利语

500×1500×820

450

300-1100

<0.5

230/50-60

0.4

6

400

700

380

425

30

技术数据变更恕不通知

Technical data subject to change without prior notice

Tool Dynamic TD 2009 Comfort:

TD 2009 舒适型刀具动平衡机

针对有远见的用户/For the ambitious

图片显示的是特殊装置: 安全罩类型3针对超过700mm的刀柄(见附件确认 从14页开始)

Picture shows special equipment: Safety hood type 3 for tools with length up to 700 mm (see optional confi gurations from p. 14)

10 技术数据变更恕不通知

Technical data subject to change without prior notice

如果你经常使用动平衡机并希望调节时间缩短,那你需要

TD2009舒适型动平衡机。它带有一台电脑、键盘、鼠标

和显示器,大屏幕让你能快速的输入数据,并且用户使用

的是图形界面,这让你的平衡调节更快。除此之外提供铣

削功能来调节平衡,铣削功能在实际应用去除大的不平衡

量是非常效用的。

技术数据变更恕不通知/Technical data subject to change without prior notice

TOOL DYNAMIC TD 2009 COMFORT

模块化动平衡系统/MODULAR BALANCING SYSTEM

技术参数/Technical details

Tool Dynamic TD 2009 Comfort

如下的功能和Tool Dynamic TD 2009 经济增强型动平衡机一样

The following characteristics are identical to Tool Dynamic TD 2009 Economic Plus:

下面的功能是TD2009舒适型动平衡机标准配置的

The following characteristics are standard inclusive for Tool Dynamic TD 2009 Comfort:

特点/Characteristics

特点/Characteristics

单平面动平衡测量功能

Balancing in 1 plane

光学指引帮助

Optical indexing help

用户界面

User interface

激光标记

Laser marking

双平面动平衡测量功能

Balancing in 2 planes

固定位置调平衡

Fixed components

自动定位

Automatic indexing

附件架

Rack for accessories

Please check the table from page 14

特殊材料的底座

Base made of polymer concrete

标签打印接口

Print label

径向钻孔去重标示软件

Drilling radial

精确测量

Index balancing

主轴补偿测量功能

Balancing with spindle compensation

动平衡环配重标示软件

Software for compensation with

balancing rings

德语/英语/法语/西班牙语/

意大利语

New software with user-friendly graphical

interface and touchscreen-control

Comfortable tray to place PC-screen

and keyboard

铣削去重标示功能

Milling program

附件和特殊装置

Accessories and special equipment

动平衡TD4.0 软件

Balancing software TD 4.0

屏幕托盘

Screen holder

PC&TFT 屏幕

PC & TFT screen

用铣削方式来调节不平衡量

从14页开始介绍

新的软件使用方便,图像集成

显示并可以通过触摸屏控制

舒适的托盘放置电脑屏幕和键

盘

带有电脑Package for comfortable usage via keyboard

(includes PC, TFT screen, keyboard, mouse)

1100×1500×820

450

300-1100

<0.5

230/50-60

0.4

尺寸/Dimensions [mm]

重量/Weight [kg]

主轴转速/Spindle speed [rpm]

测量精度/Measuring accuracy [gmm]

电源需求/Power requirements [V/Hz]

功率/Power usage [kW]

气源/Compressed air [bar]

*大刀柄长度/max. tool length [mm]

选项/optional

*大刀柄直径/max. tool diameter [mm]

选项/optional

*大刀柄重量/max. tool weight [kg]

订货号/Order No. 80.224.00.09

6

400

700

380

425

30

11 技术数据变更恕不通知

Technical data subject to change without prior notice

Tool Dynamic TD 2009 Comfort Plus:

TD 2009 舒适增强型刀具动平衡机

针对追求完美的用户/For perfectionists

图片显示的是特殊装置: 安全罩类型3针对超过700mm的刀柄(见附件确认 从14页开始)

Picture shows special equipment: Safety hood type 3 for tools with length up to 700 mm (see optional confi gurations from p. 14)

12 技术数据变更恕不通知

Technical data subject to change without prior notice

新的TD2009舒适增强型提供了*大的便利性和舒适性。在

使用TD2009舒适增强型动平衡机时,你不会感到无所适从。

不需要成为专家,你就能快速、高效的进行刀具平衡。优化

的触摸屏、集成电脑、舒适的附件抽屉等使平衡快捷、便利

并容易,这也是你毫不犹豫选择TD2009舒适增强型动平衡机

的原因。

技术数据变更恕不通知/Technical data subject to change without prior notice

TOOL DYNAMIC TD 2009 COMFORT PLUS

模块化的动平衡系统/MODULAR BALANCING SYSTEM

技术参数/Technical details

1100×1500×820

450

300-1100

<0.5

230/50-60

0.4

尺寸/Dimensions [mm]

重量/Weight [kg]

主轴转速/Spindle speed [rpm]

测量精度/Measuring accuracy [gmm]

电源需求/Power requirements [V/Hz]

功率/Power usage [kW]

气源/Compressed air [bar]

*大刀柄长度/max. tool length [mm]

选项/optional

*大刀柄直径/max. tool diameter [mm]

选项/optional

*大刀柄重量/max. tool weight [kg]

订货号/Order No. 80.226.00.09

6

400

700

380

425

30

包含触摸屏幕的动平衡控制终端

Control terminal incl. touchscreen

Tool Dynamic TD 2009 Comfort Plus

铣削去重标示功能

Milling program

下面功能是TD2009舒适型动平衡机标准中包含

The following characteristics are identical to Tool Dynamic TD 2009 Comfort:

下面功能是Tool Dynamic 2009 舒适增强型特有的

The following characteristics are standard inclusive for Tool Dynamic TD 2009 Comfort Plus:

特点/Characteristics

特点/Characteristics

单平面动平衡测量功能

Balancing in 1 plane

光学指引帮助

Optical indexing help

用户界面

User interface

激光标记

Laser marking

附件和特殊装置

Accessories and special equipment

柜架用来存放触摸屏和电脑及电脑

附件(只和TD4.0软件相关的附件)。

从14页开始介绍

双平面动平衡测量功能

Balancing in 2 planes

固定位置调平衡

Fixed components

自动定位

Automatic indexing

附件架

特殊材料的底座

Base made of polymer concrete

标签打印接口

Print label

径向钻孔去重标示软件

Drilling radial

精确测量

Index balancing

主轴补偿测量功能

Balancing with spindle compensation

动平衡环配重标示软件

Software for compensation with

balancing rings

德语/英语/法语/西班牙语/

意大利

动平衡TD4.0 软件

Balancing software TD 4.0

13 技术数据变更恕不通知

Technical data subject to change without prior notice

技术数据变更恕不通知/Technical data subject to change without prior notice

软 件订货号

Order No.

文件名称

Article name

描 述Description TD 1002 TD 2009 TD 800

Economic Economic Comfort Comfort

Plus Plus

— 震动优化底座

Vibration

optimized base

Adapted table for

optimized base

— 由特殊材料制成的

立式底座

Base made of

polymer concrete

Highest measuring

accuracy due to

heavy base

— 用户界面

User interface

Integrated user

interface for easy

handling of the

machine

— 光学指引帮助

Optical indexing

help

Indication of the

exact spindle

angle position

on display

— 激光标记

Laser marking

Indicates the position

of unbalance

and correction

with a laser

— 标签打印接口

Print label

Print balancing

result on label

— 径向钻孔去重标示

软件

Drilling radial

Balancing by

drilling radially

— 动平衡环配重标示

软件

Software for

compensation with

balancing rings

Balancing by rings

or other movable

weights

— 精确测量

Index balancing

Compensation of

measuring errors

by index balancing

(2 measuring runs,

indexing angle 180°)

— 主轴补偿测量功能

Balancing with

spindle

compensation

Quick and precise

measurement of

repetition parts (sin

gle measuring run)

— 单平面动平衡测量

功能

Balancing in 1

plane

Measuring and

compensation

of unbalance in

1 plane (static)

80.252.01 双平面动平衡测量

功能

Balancing in

2 planes

Measuring and compensation

of unbalance

in 2 planes (dy

-namic unbalance)

80.202.00 固定位置调平衡

Fixed components

Enables balancing

at predefined positions,

e.g. with

balancing screws

80.217.00 自动定位

Automatic

indexing

可调底座来减缓震动

高精度的测量必须建

立在稳重的底座基础

上

集成操作界面便于操

作

显示精确的主轴角度

标示不平衡位置和改

进位置

可与打印机连接,在

标签上打印结果

通过径向钻孔达到平

衡

用平衡环或者其它移

动方式调平衡

测试过程中的误差补

偿(2次测量,旋转

180°精确测量)

快速精确地测量重复

部分

(简单测量运行的)

在单平面测量和补偿

不平衡量(静态)

在双平面测量和补偿

动平衡 (动态)

在预定位置调节平衡

比如:使用动平衡螺

钉

主轴能自动旋转到选

定角度位置

Turns the spindle

on the selected

angle position

and simplifies

exact positioning

of spindle

包含/included 选项 — 不在可选范围内/not available

可选项目

OPTIONALL CONFIGURATIONS

14 技术数据变更恕不通知

Technical data subject to change without prior notice

包含/included 选项 — 不在可选范围/not available

TD 1002 TD 2009 TD 800

Economic Economic Comfort Comfort

Plus Plus

技术数据变更恕不通知/Technical data subject to change without prior notice

80.227.00 附件架

Rack for accessories

Storage rack with

two integrated draw

ers for balancing

adapters and

further accessories

80.212.00 铣削去重标示功能

Milling program

Milling program

allows correction

of unbalance via

milling

80.245.06 动平衡TD4.0软件

Balancing software

TD 4.0

New software with

user-friendly graphical

interface and

touchscreen-control

80.228.02 屏幕托盘

Screen holder

Comfortable tray

to place PC-screen

and keyboard

80.223.00 包含触摸屏幕的动

平衡控制终端

Control terminal

incl. touchscreen

Console for storage

of touchscreen,

keyboard, mouse,

printer, and further

accessories (only

together with Balancing

software TD 4.0)

80.229.03 触摸屏TFT monitor with

touchscreen

80.229.00

+

80.229.01

电脑和显示器

PC & TFT screen

Package for comfortable

usage via

keyboard (includes

PC, TFT screen,

keyboard, mouse)

80.229.00

+

80.229.04

电脑和触摸显示器

PC & touchscreen

Package for comfortable

usage via touchscreen

(includes PC,

sophisticated 19˝

touchscreen, key

board, mouse)

80.209.00 特殊密度功能

Specific weight

function

Enables specification

of the specific

weight of the rotor

to be balanced, if

different from steel

80.213.01 轴向钻孔去重标示

功能

Drilling axial

Enables balancing

of rotors by axial

drilling, e.g. for

grinding wheels

80.218.00 精密测量使用任意

的索引角

Index balancing

with free indexing

angle

Index balancing of

rotors which can

not be indexed

180° (e.g. Capto

chucks)

80.214.00 打印功能软件

Software for

printout of report

储存架带两个集成的

抽屉可以储存转换套

或者其它附件

用铣削方式来调节不

平衡量

新的软件使用方便,

图像集成显示并且可

通过触摸屏控制

舒适的托盘放置电脑

屏幕和键盘

用来存放触摸屏、电

脑、键盘、鼠标、打

印机等附件的柜架终

端

带触摸屏的TFT显示器

包含整套电脑和显示

器、键盘、鼠标

包含整套电脑和显示

器、键盘、鼠标

针对特殊钢材或者其

它材料,可使用此功

能

通过轴向钻孔达到平

衡

测量时不需要固定调

整180角度

(例如Capto刀柄)

打印完整测试报告Printout of a detailed

measuring

protocol (balancing

certificate)

软 件订货号

Order No.

文件名称

Article name

描 述Description

15 技术数据变更恕不通知

Technical data subject to change without prior notice

技术数据变更恕不通知/Technical data subject to change without prior notice 包含/included 选项 — 不在可选范围/not available

— 德语/英语/法语/西

班牙语/意大利语

Languages for user

interface for internal

80.229.00.

EN

英语语言包

English language

package

Windows multilingual,

keyboard

English

80.229.00.

FR

法语语言包

French language

package

Windows multilingual,

keyboard

French

80.229.00.

IT

意大利语言包

Italian language

package

Windows multilingual,

keyboard

Italian

80.229.00.

SP

西班牙语言包

Spanish language

package

Windows multilingual,

keyboard

Spanish

80.229.00.

PT

葡萄牙语言包

Portuguese

language package

Windows multilingual,

keyboard

Portuguese

80.229.00.

RU

俄语语言包

Russian language

package

User interface Russian,

Windows multilingual,

keyboard

English

80.229.00.

CN

中文语言包

Chinese language

package

User interface

Chinese, Windows

multilingual,

keyboard English

89.229.00.

JP

日语语言包

Japanese

language package

User interface

Japanese, Windows

multilingual,

keyboard English

80.245.12 使用者账户管理

User account

administration

User administration

with individual allocation

of user rights

80.245.09 禁止区域

Forbidden areas

Defined areas that

are not allowed for

the compensation

of the unbalance

80.245.10 可选择补偿区域

Alternative

compensation

positions

Calculation of alternative

positions,

when proposed

position not possible

80.245.11 优化测量时间

Optimized

measuring time

Shortened measuring

run, if measuring

accuracy is sufficient

80.232.01 保护罩类型3

Safety hood type 3

Safety hood for extra

long toolholders

with max. 700mm

length and max.

400 mm diam. (opt.

with second laser

marking from top)

TD 1002 TD 2009 TD 800

Economic Economic Comfort Comfort

Plus Plus

可选项目

OPTIONALL CONFIGURATIONS

主机操作界面的语言

多语种windows 英语

键盘

多语种windows 法语

键盘

多语种windows 意大

利语 键盘

多语种windows 西班

牙语 键盘

多语种windows 葡萄

牙语 键盘

多语种windows 俄语

键盘

多语种windows 中文

键盘

多语种windows 日语

键盘

不同用户不同权限

规定不可进行平衡调

节的区域

当补偿位置不可能时

计算替换位置

更短的测量时间,保

证测量精度有效

针对加长刀柄的保护

罩,*长高度700mm

*大直径400mm(可选

择在顶端的第二激光

源)

软 件订货号

Order No.

文件名称

Article name

描 述Description

16 技术数据变更恕不通知

Technical data subject to change without prior notice

包含/included 选项 — 不在可选范围/not available

80.232.02 保护罩类型4

Safety hood type 4

Safety hood for extra

long toolholders

with max. 700 mm

length and max.

425 mm diam. (opt.

with second laser

marking from top)

80.211.03 第二激光源

(在顶部)

2 nd Laser

(from top)

Only available for

safety hood types

3 and 4

80.203.00 动平衡螺钉组

Balancing screw

set

Set consisting of

11×10 special

screws for fine-balancing

of tool holders

with balancing

threads m6 (e.g.

shrink fit chucks

from HAIMER)

79.350.xx 动平衡环

Balancing rings

For fine-balancing of

all tool holders with

cylindrical outer diameter

(see p. 35)

80.207.01 精密电子秤

Precision scale

For highly precise

weighing of balancing

weights

80.207.12 电子秤集成软件

Software scale

integration

Automatic transfer

of rotor weight

from scale

80.207.10 刀具秤

Tool scale

Measures the weight

of the tool holder,

optional direct transfer

into the balancing

software (see

option 80.207.12)

80.215.02 动平衡报告激光打

印机

Laser printer for

balancing reports

针对加长刀柄的保护

罩,*长高度700mm

高大直径425mm(可选

择在顶端的第二激光

源)

只适合类型3和4的保

护罩

11×10组螺钉(M6)适

用于刀柄的精细动平

衡(例如HAIMER的热

缩刀柄)

适用于有圆柱外径刀

柄的精细动平衡

(见35页)

精密地测量动平衡重

量

从电子秤自动传输转

子重量

测试刀具重量,可选

择电子秤集成软件直

接传输重量到平衡软

件(

见可选项80.207.12)

打印详细动平衡报告

的激光打印机

(必须选择80.214.00

选项)

Laser printer with

Ethernet port to

print out a detailed

balancing report

(together with

option 80.214.00)

80.206.00 校正磁铁

Set of calibration

magnets

测试 培训的目的Calibration magnets

for testing, training,

and demonstration

purposes

80.200.02 产品培训

Product training

对于未来质保期必须

的技术培训

The training is

obligatory for

future warranty

claims

80.230.00 校准工具

Calibration tube

为了机器精密运行并

减少误差的校准和检

测程序

For the calibration

and testing of every

balancing machine

with the help

of a defined mass

80.215.03 标签打印机

Label printer

打印出测量结果

(短报告)

Printout of a label

with the measuring

results (short

report)

TD 1002 TD 2009 TD 800

Economic Economic Comfort Comfort

Plus Plus

技术数据变更恕不通知/Technical data subject to change without prior notice

软 件订货号

Order No.

文件名称

Article name

描 述Description

17 技术数据变更恕不通知

Technical data subject to change without prior notice

Tool Dynamic Control Terminal:

刀具动平衡机控制终端

操作更舒适/For more operating comfort

带有硬质玻璃的高质量触摸屏

High quality touchscreen with hardened glass

surface for easiest control

抽拉式键盘鼠标抽屉

Traditional input with keyboard and

mouse possible

打印机储放架

Storing Facility for Printers

附件抽屉

Drawer for accessories

附加抽屉

Additional drawer

工具和动平衡转换套储存架

Storage for balancing adapter and tools

18 技术数据变更恕不通知

Technical data subject to change without prior notice

TOOL DYNAMIC TD SOFTWARE 4.0

动平衡软件4.0

New intelligent balancing software

新的图形用户界面

New graphical user interface

图形帮助功能

Intuitive user guidance with graphical help functions

新功能:禁止区域

New feature: Forbidden areas

先进的诊断功能

Advanced diagnostic modes

新的智能化动平衡软件

动平衡现在变得更容易和人性化。用户界

面图形显示,按钮符号代替了文字输入。

通过点击鼠标或者触摸屏或者使用功能健

进行操作。

旧版本的界面依然被保留。无论是谁,以

前使用过老的界面,现在使用新界面时也

不会出现问题。

帮助功能让初学者和不常用的使用者操作

简单明了,如果需要,解释功能中的描述

可以提示使用者,在整个使用过程中引导

用户,让调节平衡变的更加简单。

- 当一些区域不允许调节动平衡时,有禁

止区域功能

- 计算可选择的平衡位置

- 新设计——更人性化

- 用触摸屏操作(可选)

- 用户权限管理系统

- 可以与外部的称重设备连接

- 帮助功能

- 测量过程中的辅助功能

- 根据机器类型确定平衡公差

- 数据备份功能

- 刀具数据文件夹管理

- 与其它系统简单数据交换,比如刀具管

理系统

除此之外,增加了新的功能

用户管理系统允许不同的进入权限。比如,

一个用户创造出新的刀具资料并确定了刀

柄的平衡精度,另一个用户只可以把存在

的数据调用出来进行平衡操作。

19 技术数据变更恕不通知

Technical data subject to change without prior notice

Tool Dynamic TD Preset:

对刀仪于动平衡一体化

针对个性化客户/For individualists

20 技术数据变更恕不通知

Technical data subject to change without prior notice

TOOL DYNAMIC TD PRESET

动平衡和测量

TOOL BALANCING AND PRESETTING

- 技术的领导者

- 高效率并且节约时间

- HAIMER的平衡转换套保证了刀柄的夹持精度

- 合理的性价比

- 只需要很小的空间

- 简单而合理的操作

- 适合所有需求的转换套

- *舒适的测量

测量

带有高精度的照相机和数码照片处理的测量

*的软件

菜单式选择的测量和平衡软件

两个被认可的系统—— 一种革新的趋势

刀具的测量和平衡是现代生产*关键的基础,显然结合两

种功能是一个好的理念。TD Preset动平衡测量型就是很好

地结合HAIMER动平衡技术和Zoller的测量技术,刀柄被夹

持在HAIMER高精度的主轴系统上,同时进行平衡和尺寸测

量。因为不需要二次装夹,这缩短了时间并提高了精度。

Software for professionals

Various options for measuring and balancing clearly arranged in menus

Two approved systems –

a trendsetting innovation

Tool balancing and presetting are key elements of modern manufacturing.

It is obviously a good idea to combine these two procedures. The Tool

Dynamic TD Preset is a perfect combination of HAIMER’s balancing tech

nology and Zoller’s measuring technology. The tool is clamped in the high

precision balancing spindle fitted with HAIMER’s proven adapter system.

This saves time and increases accuracy because the tool does not have

to be re-clamped.

– Forward-looking state-of-the-art technology by technology leaders

– Highest efficiency and saved time by combining two production stages

– Utmost precision due to high precision clamping in HAIMER’s balancing

adapters

– Reasonable price and efficiency ratio

– Needs little space

– Simple and logical operation

– Adapter for all interfaces

– Highest possible measuring comfort

Order No. 80.240.00

Presetting

Measuring system with high resolution camera and digital

photo processing

订货号. 80.240.00

21 技术数据变更恕不通知

Technical data subject to change without prior notice

Tool Dynamic TD 800:

TD 800 动平衡机

针对特殊要求/For specialists

图片显示的是特殊装置: 跳动测量控制台

Picture shows special equipment: Runout measuring console

新版

NEW

22 技术数据变更恕不通知

Technical data subject to change without prior notice

对于直径接近800mm的大型旋转件——这是你的解决方案

基于动平衡技术的TD800型动平衡机允许对更大的旋转件进行测

量,如轴承环,砂轮和涡轮。选用定制的夹持转换套你可以快速

方便地调节平衡。

TOOL DYNAMIC TD 800

特殊的动平衡机/SPECIAL BALANCING MACHINES

技术参数/Technical details

Tool Dynamic TD 800

尺寸/Dimensions [mm]

重量/Weight [kg]

主轴转速 [U/min]/Spindle speed [rpm]

测量精度/Measuring accuracy [gmm]

电源需求/Power requirements [V/Hz]

功率/Power usage [kW]

气源/Compressed air [bar]

空气消耗量/Air consumption[l/h]

*大刀柄长度/max. tool length [mm]

*大刀柄直径/max. tool diameter [mm]

*大刀柄重量/max. tool weight [kg]

订货号/Order No. 80.270.00

Your solution for big rotors up to diam. 800 mm

Based on the proven Tool Dynamic balancing technology the Tool

Dynamic TD 800 allows balancing big rotors of all kind. Bearing rings,

grinding wheels and turbine wheels. With hand tailored clamping adapters

you can balance your rotors as easy and quick as usual.

保护罩从中间分开,因此转子可以轻松放入,沉重的工件可以用吊装工具

吊入。

The safety hood is segmented and opens to the side. Thus the rotor is

accessible from above. Heavy parts can be handled by a crane.

技术数据变更恕不通知/Technical data subject to change without prior notice

1500×1910×900

550

200-1100

<0.5

230/50-60

1.0

5-6

30

750

800

110

23 技术数据变更恕不通知

Technical data subject to change without prior notice

24

新版

NEW

Tool Dynamic TD 2010 Automatic:

TD2010自动刀具动平衡机

针对*需求/For professionals

技术数据变更恕不通知

Technical data subject to change without prior notice

25

新的TD2010 automatic型动平衡机是全球真正的数控自动调节不

平衡量的综合型动平衡机。它能通过钻孔和铣削的方式,自动修

正单或双平面的动平衡,并能垂直或者水平地工作。

这款动平衡机集成了19寸的触摸屏。数字控制系统是西门子

840DSL。这个系统能和动平衡软件同时使用。

我们将动平衡推向更高标准:更快,更好,更有效

TOOL DYNAMIC TD 2010 AUTOMATIC

自动调节平衡

AUTOMATIC BALANCING TECHNOLOGY

TD2010自动型动平衡机---带立式加工中心的平衡机:*舒适,

*大的工艺可靠性,*高的效率与精度。

Tool Dynamic TD 2010 Automatic – automatic vertical CNC based

balancing machine:Maximum of comfort, maximum of process

reliability with highest efficiency and precision.

订货号. 80.260.00 Order No. 80.260.00

The new Tool Dynamic TD 2010 Automatic

The new Tool Dynamic TD 2010 Automatic is a truly universal CNC-based

balancing machine with automated correction of the unbalance. It automatically

compensates the unbalance in one or two planes by drilling,

milling or grinding. The machine can work vertically and horizontally.

The balancing machine is controlled by an integrated 19’’ touchscreen.

The numerical control is a Siemens 840DSL, which can beaccessed

simultaneously with the balancing software.

Automatic Balancing – that’s how it works

After measuring the unbalance the software calculates how deep the

machine must drill, mill or grind in order to compensate the unbalance.

The balancing spindle turns into the correct position. The integrated

CNC unit moves to the pre-selected balancing plane and automatically

removes the appropriate amount of material. Done.

Balancing could not be any quicker or easier. Errors, such as those caused

by incorrect marking on the tool holder or through inadvertently incorrect

drilling depths are no longer an issue.

– Measures and compensates unbalance in one step

– Rapid, easy and economic

– No incorrect drilling on the rotor

– Integration into automatic production lines is possible

– Specific software for particular methods of balancing available

We take balancing to the next level:

faster, better, more efficient!

TD 2010自动刀具动平衡机

Tool Dynamic

TD 2010 Automatic

提高你的效率 :*快的平衡

Improve your efficiency: balancing in record time!

标准的动平衡系统

standard balancing system

时间/Time [s] 100 200 300

5 min

<1 min

Balancing process:

Simple measuring run,

compensation and check

新的TD2010 automatic型动平衡机

在测量结束后,机器能自动计算为了达到平衡需要钻孔的深度,

以及铣切、磨削的量。然后动平衡机的主轴自动转到正确的位

置,集成的数控装置就能自动去除不平衡量。

动平衡不仅仅更快和更容易,因为失误而导致刀柄不能正确调节

平衡也将不复存在。

- 测量和补偿动平衡在一个步骤完成

- 快速 ,简单和经济

- 不会出现误操作

- 可以集成在自动化生产线中

- 特殊的软件对于特殊的平衡要求

自动调节平衡——这就是它的工作

平衡过程:

简单测量,补偿和检查

技术数据变更恕不通知

Technical data subject to change without prior notice

TOOL DYNAMIC TD 2010 AUTOMATIC

特殊的动平衡机/SPECIAL BALANCING MACHINES

你所获得的利益Your benefits at a glance

■ Correction of unbalance is fully automated by drilling, milling or grinding

in one or two planes with the help of an integrated simultaneous 4 Axis

CNC machine tool

■ Integrated and exchangeable balancing adapters clamp rotors with

highest precision. There are standard adapters for all common

interfaces and customized solutions for special purposes

■ Gripper for automated indexing (optional). It can be mounted without

any additional tools and changed together with the balancing adapter

■ Chips are removed by exhaust (suction) equipment

■ Central lubrication enables a nearly maintenance free 3 shift use

■ Balancing spindle and control box are cooled

■ Dynamic measuring mode enables shortest measuring times – balance

and control your rotors in record time!

■ Simple measuring mode: Measuring, drilling and checking in less than

1 minute!

■ Integration of robot unit is possible – embody your balancing machine

in your production line!

■ Intelligent software allows the fast and efficient re-balancing of already

balanced rotors

■ 通过集成的四轴数控装置,可以通过钻孔和铣削方式调节不平

衡量

■ 动平衡转换套可替换,并保持高精度。标准的转换套能满足客

户全面的需求,而且可以针对客户的非标情况提供特殊方案。

■ 夹持器自动翻面无需任何额外工具,它能和动平衡转换套组合安

装在一起

■ 有滤气装置和铁屑收集装置

■ 中央润滑免维护,实现三班轮流使用

■ 动平衡主轴和控制箱有冷却系统

■ 能缩短时间的动平衡测量方式——*快的测量和调节

■ 简单测量模式:测量,钻孔和检测在一分钟内完成

■ 可以与机器人单元集成——使您的动平衡机在生产线中使用

■ 智能软件能让已调节的旋转体再次有效快速的调节平衡

数控加工单位自动补偿动平衡量

Automated compensation of unbalance via CNC machining unit

集动平衡转换套和机械手一体完成自动测量

Integrated balancing adapter and gripper for automatic index measuring

26 技术数据变更恕不通知

Technical data subject to change without prior notice

27

技术数据变更恕不通知/Technical data subject to change without prior notice

TOOL DYNAMIC TD 2010 AUTOMATIC

产品特征/PRODUCT FEATURES

技术参数/Technical data

测量精度/Measuring accuracy

测量精度/Measuring accuracy < 0,5 gmm

转子范围/Limitation of the rotor

*大直径/Max. diameter 400 mm

*大长度/Max. length 600 mm

*大重量/Max. weight 50 kg

可选范围/Operational range

X-Achse/X-axis 160 mm

Y-Achse/Y-axis 400 mm

Z-Achse/Z-axis 250 mm

B-Achse/B-axis 360°

快速模式/Rapid mode 20 m/min 所有轴/on all axis

动平衡主轴/Balancing spindle

*大转速/Max. RPM 1100 U/min/rpm

*大力矩/Max. torque 35 Nm

数控单元/CNC unit

刀柄接口/Interface VDI 30

*大转速/Max. engine speed 6000 U/min 可调/adjustable

*大力矩/Max. torque 15 Nm bei/at S3-25%

*大钻孔直径/Max. drilling capacity Ø 10 mm 淬火钢硬度为HRC60/in hardened steel with HRC 60

水平方向转子尺寸的可选范围/Operational range of rotor in horizontal mode

*大直径/Max. diameter 400 mm

*大长度/Max. height 250 mm

垂直方向转子尺寸的可选范围/Operational range of rotor in vertical mode

*大直径/Max. diameter 400 mm

*大长度/Max. height 280 mm

集成控制和平衡软件

Integrated control and balancing software

技术数据变更恕不通知

Technical data subject to change without prior notice

28

更低的振动,提高机床的生产

力并且延长刀具的寿命。

平衡过的砂轮可以提高工件表面

光洁度和工件精度。

技术数据变更恕不通知

Technical data subject to change without prior notice

通过

木工刀具

平衡让刀刃避免震动并使它在

加工家具时拥有高精度。这会

提高你的生产力,达到更高的

切削能力。

平衡镗刀

获得更好的公差和圆周精度。

切削能力将提升300%。

双平面平衡铣刀盘

长的刀具必须在双平面做动平

衡消除不平衡量(动平衡)。以

达到更高的切削能力和更好的

表面加工质量。

Tools for woodworking

Balancing avoids breaking of cutting

edges and vibrations and enables

the highest accuracy at the

edges of the piece of furniture.

Thus you raise your productivity

and you can realize a higher cutting

capacity.

Balancing of fine boring heads

Get better tolerance grades and

better roundness. The cutting capacity

can be raised up to 300%.

Milling head, balancing in

two planes

Long projecting tools must be

balanced in two planes in order to

eliminate the couple unbalance

(dynamic balancing). At longer tools

that leads to a higher cutting capacity

and a better surface finish.

29 技术数据变更恕不通知

Technical data subject to change without prior notice

木工刀具调整动平衡,减少了加

工中的振动。此外,在加工时将

噪音降到*低。

30

整

体刀具

技术数据变更恕不通知

Technical data subject to change without prior notice

技术数据变更恕不通知/Technical data subject to change without prior notice

HSK接口动平衡转换套

BALANCING ADAPER HSK

– μm precise clamping for highest measuring

accuracy and repeatability

– Easy and quickest changing due to compact

design

HSK接口

HSK interface

转换套订货编号

Adapter Order No.

通用

Analogy

描述

Description

HSK 25

E 80.201.E25.00 针对HSK-E25的夹持系统/Adapter for HSK-E25 with clamping system

HSK 32

AB

CDEF

80.201.A32.00 针对HSK-A32的夹持系统/Adapter for HSK-A32 with clamping system

80.201.E25.00 B32= E25 针对HSK-E25的夹持系统/Adapter for HSK-E25 with clamping system

80.201.A32.00 C32= A32 针对HSK-A32的夹持系统/Adapter for HSK-A32 with clamping system

80.201.E25.00 D32= E25 针对HSK-E25的夹持系统/Adapter for HSK-E25 with clamping system

80.201.E32.00 针对HSK-E32的夹持系统/Adapter for HSK-E32 with clamping system

80.201.E25.00 F32= E25 针对HSK-E25的夹持系统/Adapter for HSK-E25 with clamping system

HSK 40

AB

CDEF

80.201.A40.00 针对HSK-A40的夹持系统/Adapter for HSK-A40 with clamping system

80.201.E32.00 B40= E32 针对HSK-E32的夹持系统/Adapter for HSK-E32 with clamping system

80.201.A40.00 C40= A40 针对HSK-A40的夹持系统/Adapter for HSK-A40 with clamping system

80.201.E32.00 D40= E32 针对HSK-E32的夹持系统/Adapter for HSK-E32 with clamping system

80.201.E40.00 针对HSK-E40的夹持系统/Adapter for HSK-E40 with clamping system

80.201.E32.00 F40= E32 针对HSK-E32的夹持系统/Adapter for HSK-E32 with clamping system

HSK 50

AB

CDEF

80.201.A50.00 针对HSK-A50的夹持系统/Adapter for HSK-A50 with clamping system

80.201.E40.00 B50= E40 针对HSK-E40的夹持系统/Adapter for HSK-E40 with clamping system

80.201.A50.00 C50= A50 针对HSK-A50的夹持系统/Adapter for HSK-A50 with clamping system

80.201.E40.00 D50= E40 针对HSK-E40的夹持系统/Adapter for HSK-E40 with clamping system

80.201.E50.00 针对HSK-E50的夹持系统/Adapter for HSK-E50 with clamping system

80.201.E40.00 F50= E40 针对HSK-E40的夹持系统/Adapter for HSK-E40 with clamping system

HSK 63

AB

CDEF

80.201.A63.00 针对HSK-A63的夹持系统/Adapter for HSK-A63 with clamping system

80.201.E50.00 B63= E50 针对HSK-E50的夹持系统/Adapter for HSK-E50 with clamping system

80.201.A63.00 C63= A63 针对HSK-A63的夹持系统/Adapter for HSK-A63 with clamping system

80.201.E50.00 D63= E50 针对HSK-E50的夹持系统/Adapter for HSK-E50 with clamping system

80.201.E63.00 针对HSK-E63的夹持系统/Adapter for HSK-E63 with clamping system

80.201.E50.00 F63= E50 针对HSK-E50的夹持系统/Adapter for HSK-E50 with clamping system

Weinig

Weinig 80.201.W63.00 针对威力刀柄的转换套/Adapter for Weinig tool holder

HSK 80

AB

CDEF

80.201.A80.00 针对HSK-A80的夹持系统/Adapter for HSK-A80 with clamping system

80.201.E63.00 B80= E63 针对HSK-E63的夹持系统/Adapter for HSK-E63 with clamping system

80.201.A80.00 C80= A80 针对HSK-A80的夹持系统/Adapter for HSK-A80 with clamping system

80.201.E63.00 D80= E63 针对HSK-E63的夹持系统/Adapter for HSK-E63 with clamping system

80.201.E80.00 针对HSK-E80的夹持系统/Adapter for HSK-E80 with clamping system

80.201.E63.00 F80= E63 针对HSK-E63的夹持系统/Adapter for HSK-E63 with clamping system

HSK 100

AB

CDEF

80.201.A10.00 针对HSK-A100的夹持系统/Adapter for HSK-A100 with clamping system

80.201.E80.00 B100= E80 针对HSK-E80的夹持系统/Adapter for HSK-E80 with clamping system

80.201.A10.00 C100= A100 针对HSK-A100的夹持系统/Adapter for HSK-A100 with clamping system

80.201.E80.00 D100= E80 针对HSK-E80的夹持系统/Adapter for HSK-E80 with clamping system

80.201.E10.00 针对HSK-E100的夹持系统/Adapter for HSK-E100 with clamping system

80.201.E80.00 F100= E80 针对HSK-E80的夹持系统/Adapter for HSK-E80 with clamping system

HSK 125

A 80.201.A125.00 针对HSK-A125的夹持系统/Adapter for HSK-A125 with clamping system

HSK 动平衡转换套自动夹持系统/HSK balancing adapter with automatic clamping system

- μm 级的高测量精度和重复夹持精度

- 紧密的设计缔造简单和快速

技术数据变更恕不通知

Technical data subject to change without prior notice 31

1) 也适合BIG(大昭和)系列刀柄技术数据变更恕不通知

Technical data subject to change without prior notice

SK/BT/CAT/FFT/CAPTO/KM 接口动平衡转换套

BALANCING ADAPTER SK/BT/CAT/FFT/CAPTO/KM

SK/BT/CAT/BBT接口动平衡转换套和自动夹持系统

SK/BT/CAT/BBT balancing adapter with automatic clamping system

订货号/Order No. 锥度尺寸/for taper size 拉钉/for pull stud

80.201.330.01 SK30/BT30/BBT301) Gewinde/thread M12

80.201.330.01.IN CAT30 Gewinde/thread 1/2”-13

80.201.330.02 SK30/BT30/BBT301) DIN 69872/MAS 30°/45°/90°

80.201.330.04 SK30 ISO 7388

80.201.140.01 SK40 DIN 2080 Gewinde/thread M16

80.201.340.01 SK40/BT40/BBT401) Gewinde/thread M16

80.201.340.01.IN CAT40 Gewinde/thread 5/8”-11

80.201.340.02 SK40/BT40/BBT401) DIN 69872/JIS B6339

80.201.340.04 SK40 ISO 7388

80.201.340.06 BT40 MAS 30°/45°/90°

80.201.150.01 SK50 DIN 2080 Gewinde/thread M24

80.201.350.01 SK50/BT50/BBT501) Gewinde/thread M24

80.201.350.01.IN CAT50 Gewinde/thread 1”-8

80.201.350.02 SK50/BT50/BBT501) DIN 69872/JIS B6339

80.201.350.04 SK50 ISO 7388

80.201.350.06 BT50/BBT501) MAS 30°/45°/90°

订货号/Order No. 锥度尺寸/for taper size

80.201.9C3.10 Capto C3

80.201.9C4.10 Capto C4

80.201.9C5.10 Capto C5

80.201.9C6.10 Capto C6

80.201.9C8.10 Capto C8

80.201.9C10.10 Capto C10

订货号/Order No. 锥度尺寸/for taper size

80.201.KM40.00 KM40

80.201.KM50.00 KM50

80.201.KM63.00 KM63

80.201.KM80.00 KM80

80.201.KM100.00 KM100

80.201.KM125.00 KM125 (按需求定作/upon request)

– μm precise clamping for highest measuring

accuracy and repeatability

– Easy and quickest changing due to compact

design

- μm 级的高测量精度和重复夹持精度

- 紧密的设计缔造简单和快速

Capto接口动平衡转换套和自动夹持系统/Balancing adapter Capto with automatic clamping system

KM接口动平衡转换套和自动夹持系统/Balancing adapter KM with automatic clamping system

32 技术数据变更恕不通知

Technical data subject to change without prior notice

技术数据变更恕不通知

Technical data subject to change without prior notice

新版

NEW

HG动平衡转换套/HG balancing adapter (HG01/02/03)

HG-夹头/HG collet

(HG01/02/03)

夹持锁/Bayonet lock

技术数据变更恕不通知/Technical data subject to change without prior notice

HG 动平衡转换套

HG BALANCING ADAPTER

Balancing adapter for tools with shank

– For efficient and automatic clamping of tools with shank

– For cylindrical shanks up to tolerance h8

– Available with shank diameter up to 40 mm upon request

Balancing adapter with exchangeable high precision collets (system HG)

and automatic clamping. From now on you can clamp your shank-tools

directly in the balancing adapter without any accessories.

HG-转换套/HG adapter 夹套/Collet 夹持范围/Clamping range D

订货号/Order No. 订货号/Order No.

HG01 HG01 Ø 2–9 mm

80.201.HG01.00 80.201.HG01.02 2 mm

80.201.HG01.02.5 2,5 mm

80.201.HG01.03 3 mm

80.201.HG01.1/8Z 1/8 ”

80.201.HG01.04 4 mm

80.201.HG01.04.5 4,5 mm

80.201.HG01.3/16Z 3/16 ”

80.201.HG01.05 5 mm

80.201.HG01.05.5 5,5 mm

80.201.HG01.05.6 5,6 mm

80.201.HG01.06 6 mm

80.201.HG01.06.3 6,3 mm

80.201.HG01.1/4Z 1/4 ”

80.201.HG01.07 7 mm

80.201.HG01.07.1 7,1 mm

80.201.HG01.5/16Z 5/16 ” mm

80.201.HG01.08 8 mm

80.201.HG01.09 9 mm

HG02 HG02 Ø 10–14 mm

80.201.HG02.00 80.201.HG02.3/8Z 3/8 ”

80.201.HG02.10 10 mm

80.201.HG02.11 11 mm

80.201.HG02.7/16Z 7/16 ”

80.201.HG02.12 12 mm

80.201.HG02.12.5 12,5 mm

80.201.HG02.1/2Z 1/2 ”

80.201.HG02.14 14 mm

80.201.HG02.9/16Z 9/16 ”

HG03 HG03 Ø 16–20 mm

80.201.HG03.00 80.201.HG03.5/8Z 5/8 ”

80.201.HG03.16 16 mm

80.201.HG03.18 18 mm

80.201.HG03.3/4Z 3/4 ”

80.201.HG03.20 20 mm

针对直柄刀具的动平衡转换套

- 自动高效地夹持直柄刀具

- 可夹持公差达到h8的圆柱柄刀具

- 夹持刀柄直径达到40mm以上的,可按要求订作

动平衡转换套可更换高精度的夹套并且自动夹

持。从现在起你可以直接夹持直柄刀具作动平

衡而不需要任何附件。

33

技术数据变更恕不通知

Technical data subject to change without prior notice

动平衡芯轴

BALANCING ARBOUR

– To balance tools with cylindrical bore

– Precise centrically clamping for highest repeatability

– Fine balanced to < 1gmm

– Individual useable

动平衡轴

Balancing arbour

夹套

Collet

夹持范围

Clamping range Ø D

LL

订货号/Order No. 订货号/Order No.

DG07, 夹持范围/Clamping range 25–34,5 mm

80.250.A63.070 80.250.07.25 Ø 25–25,5 100

80.250.07.26 Ø 26–26,5 100

80.250.07.28 Ø 28–28,5 100

80.250.07.30 Ø 30–30,5 100

80.250.07.32 Ø 32–32,5 100

80.250.07.34 Ø 34–34,5 100

DG08, 夹持范围/Clamping range 35–44,5 mm

80.250.A63.080 80.250.08.35 Ø 35–35,5 100

80.250.08.36 Ø 36–36,5 100

80.250.08.38 Ø 38–38,5 100

80.250.08.40 Ø 40–40,5 100

80.250.08.42 Ø 42–42,5 100

80.250.08.44 Ø 44–44,5 100

DG09, 夹持范围/Clamping range 45–54,5 mm

80.250.A63.090 80.250.09.45 Ø 45–45,5 125

80.250.09.48 Ø 48–48,5 125

80.250.09.50 Ø 50–50,5 125

80.250.09.52 Ø 52–52,5 125

80.250.09.54 Ø 54–54,5 125

DG10, 夹持范围/Clamping range 55–64,5 mm

80.250.A63.100 80.250.10.55 Ø 55–55,5 135

80.250.10.58 Ø 58–58,5 135

80.250.10.60 Ø 60–60,5 135

80.250.10.62 Ø 62–62,5 135

80.250.10.64 Ø 64–64,5 135

你需要订一个动平衡芯轴和一个夹套

By ordering you need one balancing arbour and one collet

Balancing arbour with automatic clamping:

Special balancing arbours tailored for your production

process available on request.

- 平衡带有中心圆孔的工具

- 高的夹持精度和重复精度

- 良好的平衡<1gmm

- 十分实用

自动夹持的动平衡芯轴:

特殊的动平衡芯轴为你需要的产品特殊定制

34 技术数据变更恕不通知

Technical data subject to change without prior notice

技术数据变更恕不通知

Technical data subject to change without prior notice

技术数据变更恕不通知/Technical data subject to change without prior notice

动平衡环/BALANCING RINGS

动平衡螺钉/SET OF BALANCING SCREWS

For fine-balancing of all tool holders with cylindrical outer diameter

(diam. A)

The balancing rings have a defined unbalance in themselves. They are

turned in such a position that the unbalance of the tool holder will be

compensated. There are always 2 rings needed per balancing plane.

上海挚震实业有限公司18916076644内容声明:谷瀑为第三方平台及互联网信息服务提供者,谷瀑(含网站、客户端等)所展示的商品/服务的标题、价格、详情等信息内容系由店铺经营者发布,其真实性、准确性和合法性均由店铺经营者负责。谷瀑提醒您购买商品/服务前注意谨慎核实,如您对商品/服务的标题、价格、详情等任何信息有任何疑问的,请在购买前通过谷瀑与店铺经营者沟通确认;谷瀑上存在海量店铺,如您发现店铺内有任何违法/侵权信息,请在谷瀑首页底栏投诉通道进行投诉。上海挚震实业有限公司 电话:021-67194494 手机:18916076644 地址: 上海市奉贤区南桥镇南桥路311号

上海挚震实业有限公司18916076644内容声明:谷瀑为第三方平台及互联网信息服务提供者,谷瀑(含网站、客户端等)所展示的商品/服务的标题、价格、详情等信息内容系由店铺经营者发布,其真实性、准确性和合法性均由店铺经营者负责。谷瀑提醒您购买商品/服务前注意谨慎核实,如您对商品/服务的标题、价格、详情等任何信息有任何疑问的,请在购买前通过谷瀑与店铺经营者沟通确认;谷瀑上存在海量店铺,如您发现店铺内有任何违法/侵权信息,请在谷瀑首页底栏投诉通道进行投诉。上海挚震实业有限公司 电话:021-67194494 手机:18916076644 地址: 上海市奉贤区南桥镇南桥路311号 扫一扫,手机浏览

扫一扫,手机浏览